For painting walls of a large area, various devices are often used. One of them is a roller. With it, you can not only paint the walls, but make the room stylish and unusual. This is achieved due to the textured coating of the roller, which creates an imprint on the wall that imitates various surfaces or pattern.

The variety of rollers for allows you to create an original pattern. Previously, rollers were made from improvised means, today finished products are sold, which greatly simplify the work of the master. At the same time, the purchase costs are paid off due to the possibility of repeated use.

There are several types of rollers, but all of them are united by the simplicity of design. Any wall roller consists of a holding rod, a cylinder and a nozzle. Tool Benefits:

- significantly reduces the time for surface treatment;

- the design allows you to quickly replace the outer part;

- provides uniform painting of walls without streaks and smears;

- by adding an extension to the handle, you can handle the ceiling and other remote surfaces.

With all its advantages, the wall roller has some disadvantages. They cannot paint over the corners and hard-to-reach places, for them you will have to use a narrow roller or brush. Uneven surfaces are also impossible to paint with such a tool.

When choosing a roller, take into account the amount of work. For painting large areas smooth walls ideally suitable tool on a long handle and with a large fur coat. When knurling stencils, processing corners, a mini-design is used. The handle should be comfortable, not slippery. Modern designs have special clamps for fixing the extension cord. Such additions lead to an increase in the cost of the instrument, so it is worth considering in advance whether they are needed or not.

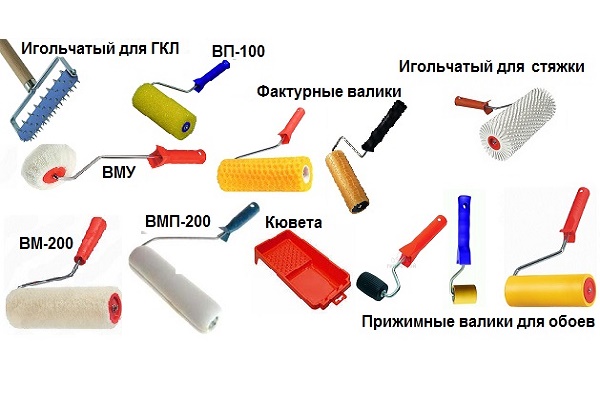

Types of rollers

Simplicity of design combined with excellent functionality make rollers indispensable for painting walls. A variety of sizes allows you to distinguish the following types:

- mini - due to its small size, hard rubberized base is convenient for applying stencils, processing corners and small areas;

- midi - the most popular size used for painting any surface;

- special - used when working with structural paints, aggressive materials, for processing uneven surfaces.

For decorating walls, a structural roller is used, which can be used different ways. For the first option, a tool is suitable, on the surface of which a pattern is applied. By passing it along the wall, they create a repeating image, similar to how it looks on the wallpaper. The second option involves using a roller to give the wall the desired texture. It should have a rough surface, due to which the pattern is formed. Depending on the expected effect, the tool is selected.

Basic working part roller is a fur coat made of different materials. Choice working surface depends on what pattern the wall will be covered with, as well as on the characteristics of the walls being processed. To create the desired texture on them by applying a repeating pattern, a thread roller is used. It is suitable for painting with polyurethane or polyamide paints. A similar purpose and principle of use for a perforated roller. It is also used to create structural coatings.

It is convenient to apply water-dispersion paints with a tool with artificial fur. He is distinguished by good operational properties contributing to durability and strength. Fur attachment is often used to create decorative surface. The length of the pile is selected taking into account the quality of the base. The more roughness, the longer the pile should be.

Due to its softness, the felt fur coat is suitable for any surfaces. In addition, it tolerates contact with aggressive compounds well. A good felt is suitable for smooth and rough surfaces. For painting with oil, water-dispersion paints or compositions with solvents, a nylon coat is often used.

![]()

Nozzles are produced different sizes, they are easy to match to any type of roller. Due to this, the desired effect is achieved regardless of the area and configuration of the walls.

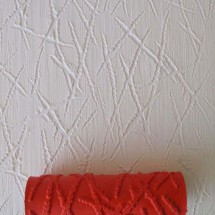

texture roller

Separately, one should dwell on the relief rollers. On their surface there are recesses and irregularities that create a certain pattern on the wall. The texture roller allows you to apply a pattern to the base. Moreover, the drawing can be abstract or quite definite. When choosing a pattern, it should be borne in mind that a large pattern looks good in spacious rooms. If the room is small, then it is better to give preference to a small pattern, without sharp transitions.

It is not difficult to work with such a tool, but you need to know some features. If, when painting walls with an ordinary roller, the strips need to be overlapped, then the pattern is applied end-to-end with a decorative nozzle. In addition, it is necessary to control the symmetry of the ornament.

There is a special design of two rollers. One of them - foam rubber - is intended for painting, and the second - rubber - for knurling a pattern. The technology of staining with such a tool is simple. First prepare the wall. It is cleaned of the old coating, puttied and primed. After drying, the primer is applied base layer paints. Then, in the pan, the foam part is saturated with paint of a different color. The structural part is connected and rolled over the pallet, slightly squeezing out the excess. The prepared tool is carried out from top to bottom along the wall, leaving a patterned path. Then apply the roller exactly to the edge of the first strip and apply the next strip.

The textured roller can be made independently. To do this, take an ordinary roller and wind ropes around it. different section. The result will be a texture similar to the bark of a tree. If a strongly crumpled fabric is wound on the base, then the effect of “frosty glass” can be obtained. To do this, the wall is first painted base color let it dry. The second layer should be contrasting. To make it thinner, the paint is made liquid. Until the second layer has dried, it is carried out with a rag roller in different directions, removing part of the paint. The result will be the appearance of a "frosty pattern" on the wall.

Roller mounting options

The ease of use of the tool depends on the reliability of attaching the roller to the handle. There are 2 types of fastening: frame and clasp.

Bugel creates secure fixation roller, making it reusable. When replacing the nozzle or coat, the roller becomes like new and can be used with other paints. Thanks to a small groove on the clasp, you can easily remove or fix the roller.

Distinctive feature frame system is a special roller design. It includes a bearing, plastic plugs, a lock. The fur coat is fixed by a special mechanism consisting of a rotational element and limiters.

Features of work

Simple rules will help to avoid uneven wall painting and material overruns. Tools and the paint container must be kept clean. You should first check the roller with a fur coat made of foam rubber or fur: does it leave lint or stains on the surface. The roller should rotate evenly, there should be no traces of rust on the metal.

Before staining, you should decide on the need for additional adapted and tools (mini-rollers, extension cords). Using a texture roller, it is necessary to strictly observe the technology, take into account the drying time of the paint. Otherwise, even the most expensive tools will not provide a quality result.

Before applying paint to the wall, the excess must be removed from the roller. It is recommended to test the roller in an inconspicuous place first. When applying paint, you should control the pressure. If it is unstable, then the surface will turn out to be unevenly colored.

Create unique interior and comfort in the house is easy and interesting with a patterned roller for wall decor. Art painting any surface is now available to everyone. Do you want to decorate the walls with a classic or original openwork pattern? You only need a few materials: paint in your favorite color, patterned rollers and a frame for them. This simple set will give each room its own charm. Any meager, bare walls in a couple of strokes will take on a unique look.

Most importantly, patterned rollers can be used by anyone. Even without experience in this area. A large assortment of rollers and detailed descriptions for each of them will help you make this difficult choice. In our store you can choose the goods to your taste. The cost of the rollers is justified by the quality and durability. The online store "Tsvetnoe" presents rollers only from the most the best manufacturers time-tested.

Pattern of new life in your hands

Patterned rollers you can buy in our online store, from the variety of patterns choose the one that will delight you every day. It is worth discarding all doubts and diversifying your life bright colors and interesting patterns. Perhaps making this choice will be the most difficult step in creative process decoration. Most likely, you will want to buy several patterned rollers for painting walls at once. The rest is a matter of technique. Similar information about correct use You will find patterned rollers in the description of each offer. There you will find inspiration to get started. The process itself will already bring pleasure, because you do everything with your own hands. And the price of a patterned roller for wall decor will increase your desire to diversify the interior when it takes a minimum of time to work. Do not deny yourself such pleasure!

Decorative roller constantly used in finishing work using structural plaster. In addition, it can be improved or made by hand. Homemade roller - a budget option, with which you can qualitatively perform wall cladding independently and to your taste.

![]() With the help of a homemade roller, you can make original decor on the walls

With the help of a homemade roller, you can make original decor on the walls

Updated old do-it-yourself roller

It is not difficult to make a modernized decorative roller, especially if an old foam rubber roller is lying around in the house, the household has a simple cord, a clothesline (50 cm is enough), a plastic bag, scissors, a knife and adhesive tape. On a separate section of any of the walls, after covering it with decorative plaster, you can try these options and choose the right one:

- To improve the appearance of the plaster, to create a decorative pattern on it, a cord and a clothesline are wound around the old roller. The type of pattern will depend on their thickness. A distinct rhythm will appear on the wall. Its regularity can be controlled by the number of passes, the frequency of turns and direction. An unusual pattern appears from the depressions on the roller.

- An old styrofoam roller will also come in handy. With it, you can make a patterned pattern with bulges. First, cuts are made with a knife, then cuts of any diameter are made with scissors. A wide bulge will appear from the thickness of the cutout, which will build the pattern.

- A textured roller will be if you put on a soft sleeve rewound with a thread.

Any of these rollers can add a beautiful shape, attractive depth to the walls on the finishing layer of plaster, or completely change the interior of your house or apartment. If there is no old roller, you can easily make a new one yourself.

Roller from improvised materials

The design of the roller for painting walls and ceilings

The design of the roller for painting walls and ceilings For the future decorative roller, you must first make the base - the cylinder. There are several options for obtaining an elongated item cylindrical shape required for the base:

- Rolling pin for the test. Since it is wooden, it is easy to drill a hole in it along its entire length. A thick wire or a metal bar, curved in the form of a handle, is inserted into the hole. You can use a pen from an old roller.

- Plastic pipe (d=5 cm, l= 10 cm). To close the side holes in the pipe, plugs are cut out of plastic, which are put on glue, holes for the handle are also made in them.

- If there's lathe, on it you can carve a roller from metal, rubber, plastic, or wood, and then fix the handle in it.

If you have a base, you can start making a decorative roller. From a randomly wound cord on a prepared layer of plaster, a one-of-a-kind relief pattern will be obtained.

From plastic bag, ordinary vegetable mesh, wound on a base, made by hand and fixed with adhesive tape, a pattern will appear on the wall with sinuous folds, uneven wrinkles.

Cellophane can be replaced with any fabric material. Foam rubber lying around in the house is also used. After fixing it with adhesive tape homemade tool, drawings are cut out on it. The manufacturing process of such a roller is laborious, but as a result, the wall will be a real decoration of the room. If there is no foam, you can find a piece of rubber. Of course, it is more difficult to cut on rubber, but the quality of the pattern will be noticeably higher. To obtain a longitudinal structural pattern, a tool is made with bulges on the surface.

Decorative roller from shreds of fabric and foam rubber

Decorative roller from shreds of fabric and foam rubber Proper application of plaster

The use of a roller, which you can do yourself, will be appropriate if you follow all the application rules decorative plaster on the walls:

- The surface that they intend to update must be prepared - cleaned of old finish(paint, wallpaper), degrease and coat with a primer.

- If the master is going to apply two layers of plaster, then first a smooth layer with a flat surface is made and painted in the desired color.

- After that, a rich structural second layer of plaster is applied to the wall. If the interior requires it and it is necessary to clearly distinguish between layers, a special adhesive tape is used. For freeform a self-adhesive sealant is used, which is used on windows.

- It should be borne in mind that the plaster has a quick-drying property, so the textured pattern should be applied quickly.

- It is undesirable to press the tool on the plastered surface; you can accidentally spoil the intended texture. Movements should be light, sliding.

- After the decorative layer has been completely applied (after about 20 minutes), a wet mesh is applied to grind the protrusions on the finished relief surface.

- After two days, (this optimal time for complete drying of walls and plaster), the entire surface is completely cleaned from defects. After that, it is covered with paint of the desired color.

Choosing a variety of textured coating for the roller, it is necessary to represent the final result.

If you put on a sleeve with a pile on the base of the roller, you can make a structural relief “under a fur coat”. It is more often used for concrete, brick exterior walls. In this case, the pile must be at least 18 cm long.

Working with a textured do-it-yourself roller is suitable not only for creative people. Everyone who has the desire to create in the house original interior, will be able to make it from ordinary improvised materials.

empstenup/ March 15, 2016 / /

Treatment of the wall in the room with large area in the vertical plane involves the use various tools. One of them is a roller for decorative painting. With your own hands, this tool can be assembled from improvised materials, or you can purchase it already ready product. The roller is very easy to handle. Additionally, sets of nozzles with different textures are sold. With their help, you can create various effects on the wall.

Equipment

The design of the rollers is as simple as possible. The instrument has working part, which is in direct contact with the walls, with a coloring composition. This is a plastic cylinder. meet and wooden varieties, but much less often. The surface of the cylinder is covered with nozzles and materials with various properties. The quality of the result of the work depends on the characteristics of these coatings.

Do-it-yourself metal bushings are pressed into through holes. The latter are located at the ends of the cylinder. The clasp handle is attached to the axis, which itself is threaded into the holes.

On the axis there is a thread from the end through which the roller is put on. A lock nut is usually placed here. Sometimes a fixing cotter pin is placed inside. It needs a recess with a different shape. The cylinder freely rotates around its axis due to the design features in the assembled form.

The handle of the tool has a smooth surface or rough. If the tool is professional, the grip area is covered with rubber. To install the tool with your own hands on the bar, a special cavity is located on the handle from the end. Thanks to this, painting the upper sections of the walls does not take much effort.

Practical use

The working part of the tool is selected individually, depending on what texture you need to apply the material with your own hands, what coating is to be processed.

First, we put the cylinder with an outer coating on the axle with our own hands. For professional tools there are so-called uniform cylinders. They wear covers made of different materials.

Productivity will increase if you use only suitable texture rollers with your own hands. It also allows you to apply a coating by changing the shading in different places, use substances with different composition.

If the wall roller is of high quality, then the paint is applied without splashes and other traces. And the coating itself does not contain traces of wax. At right choice You can save a lot of time for processing large areas.

Mount type

- The roller in thermoglued modification. In this case, the fur coat is glued to the surface of the core by the method of thermosynthesis. Such nozzles are considered durable. Therefore, they are often recommended to professional masters. No seam - important feature designs. But such devices themselves are more expensive compared to the closest analogues.

- With knitted coats. The parts are fixed directly on the core with an adhesive base. Most often, foam rubber rollers are produced in this way. The characteristics of the adhesive used determine how high-quality and durable the tool itself for decorative finishing will be.

- With interchangeable coats for painting. Plugs are used for fastening.

Coat materials

One or another work surface for painting must be chosen depending on the features that you will encounter when performing painting works for walls. Case materials - the main difference between different models nozzles that are available on the modern market.

According to the results of the work, the textures of the cover and the surface of the wall will fully correspond to each other. Hiding power - the area of \u200b\u200bthe walls that you can cover with your own hands at a time. The length of the pile determines what this characteristic will be.

The following materials are used in production most often. Everyone performs a decorative function in approximately the same way.

- A polyester paint roller is a cheap tool but cannot boast of durability. Coloring composition well impregnated fibers. No less qualitative paint is transferred to another surface. There is no pile on the finished coating.

- Polyacrylic roller — great option for water based paints. Or for compositions in which a minimum of aggressive substances. They have a pile with different lengths. The latter is determined functional characteristics tool.

- Polyamide roller of artificial origin. Has high wear resistance. The material is not deformed under the influence of aggressive substances. Therefore, it can be used to apply different colors with your own hands. The fibers are most often 2 cm long.

- Rollers with wool fibers perfectly distributed for walls paints and varnishes have good absorbency.

- Roller with velours for walls contain polyamide fabric. On top of the product, the texture resembles plush fabrics. Suitable to work even with oil paints. The roller is good because it does not splatter the paint when applied.

- Flock fibers are made on the basis of polyurethane. In an electrostatic field, they are glued to fabric bases. These are durable and strong coats. Differ in a high rate of wear resistance. Suitable for smooth surfaces.

Foam rubber is characterized by the ability to return to its original shape after deformation. They practically do not stick. Such devices will help to apply even water-dispersion paint. But the surface is not able to withstand chemically aggressive substances.

Tools with interchangeable wall coats usually cost more. You should not choose such rollers if the work will be one-time.

A special painting ditch is a must-have addition to the purchase. Such a part is supplied with a ribbed surface. A tool soaked with paint can be rolled over it, which will allow you to remove excess material that is not needed.

Several different instruments for painting or replacement coats will be useful in situations where solvent formulations are used. It is recommended to wrap the tool tightly in plastic bags when you need to store it in its original state for several days.

Both painters and designers use devices for the same degree. Convex drawings on the surface will allow you to create any pattern, not only abstract, but also quite definite.

2 videos about decorative paint rollers

Types of rollers in pictures (35 photos)

![]()

The use of decorative plaster as finishing material has long ceased to be something exotic. Its use in the design of the interiors of apartments or public institutions, as well as the facades of houses, allows you to get a durable and durable coating resistant to damage and wear.

Additional advantages include the absence of seams and joints on the surface, which significantly increases the aesthetic value of the finishing material, and one can talk endlessly about decorative qualities. Rollers for decorative plaster, which are best suited for working with this finishing material, will help to translate the idea into reality.

Varieties of rollers.

A smooth painted wall is good, but an interior with such elements does not look original and does not represent any artistic value. Applying plaster with a roller can solve this problem, and depending on the type of tool itself, you can get amazing volumetric effects on the surface of the walls. In addition, the use of a roller can increase productivity several times: short term the maximum area can be treated.

roller for textured plaster is a cylinder fixed on the handle, a special coating is applied to the surface of the roller, due to the texture of which the necessary relief is created on the decorative coating.

Before choosing a tool, you should determine which decorative plaster is applied with a roller, because in addition to it, craftsmen use spatulas, brushes, etc. First of all, this is for facade and internal works, fine and Venetian - for rooms. The granules that make up the material must be small size, to decorative effect when using the roller was maximum.

Before choosing a tool, you should determine which decorative plaster is applied with a roller, because in addition to it, craftsmen use spatulas, brushes, etc. First of all, this is for facade and internal works, fine and Venetian - for rooms. The granules that make up the material must be small size, to decorative effect when using the roller was maximum.

All rollers for decorative plaster are conventionally divided into two categories:

- by the type of material of the working surface of the tool itself;

- according to the type of pattern left on the surface.

Types of rollers according to the material of the working surface.

The working surface of the tool directly affects the final result. Today, there are several groups of rollers that are used when applying decorative plaster.

- Rubber. On the roller of such a tool, various protrusions or recesses are located, due to which the necessary effect is created on the surface of the wall. Such a device is well suited for imitating a clear texture: masonry, patterns, etc. Rubber rollers are most often used experienced craftsmen, because they require certain skills in working with plaster.

- Wooden. The tool is similar to rubber for its intended purpose, but it is easier to work with it, because when applied, the plaster sticks less to its surface. In addition, the tree is environmentally friendly. pure material and will not enter with the composition in chemical reaction(this can be useful when decorating a children's room). Over time, the wooden roller can swell from constant contact with water, so after each use it should be thoroughly cleaned and dried.

- Plastic. Cheap analogue rubber. With use, deformation of its surface and the appearance of cracks are possible, which can adversely affect the final result.

- Leather. With their help decorative coating takes on the effect of marble. Leather rollers are indispensable for applying to walls. For work better fit a roller made of genuine leather, capable of providing the highest quality result, in addition to everything, it will last much longer than artificial analogues.

- Pile. The fur coat of such a roller is made of artificial (acrylic, polyamide) or natural fur of various lengths. The length of the pile affects the relief, the smaller it is, the smoother the surface will be. The quality of the tool is very important, when buying, you should pay attention to the durability of the pile, if it “climbs”, then all the hairs that have fallen out will settle on the plaster and ruin the final coating.

In addition to these types, foam, fabric and foam rubber rollers are used, which create various roughnesses on the walls. For example, the use of the latter creates the effect of bursting bubbles or craters on the plaster.

Important: Pressure on the roller when applying a textured coating is not welcome. How less power pressing, the more pronounced the effect. Movements when working with the tool should be smooth, sliding in the direction from top to bottom and as continuous as possible.

Rollers for textured plaster are produced in the following sizes:

- up to 30 cm (short);

- 30-50 cm (medium);

- from 50 cm (long).

Depending on the desired result and the surface area on which the textured plaster is applied, the appropriate width of the tool is selected.

Types of rollers according to the type of final drawing.

Depending on the desired pattern or texture, the following types of decorative plaster rollers are used, even with your own hands you can create unique decorative elements with their help.

1. Textured rollers. Such tools are able to imitate the most different materials: fur, marble, textiles, wood, etc.

The relief on the plane of the wall is achieved due to the corresponding surface of the roller itself. For example, in order to obtain decorative plaster with a “fur coat” effect, it must be applied with a long-haired roller.  surface that mimics a natural stone, is obtained by using a roller with a looped pattern in the form of "ears".

surface that mimics a natural stone, is obtained by using a roller with a looped pattern in the form of "ears".

Textured rollers for decorative plaster are indispensable for obtaining the effect of marble; rollers with leather or fabric nozzles are used for this. In order for the texture to be as realistic as possible, it is important to move the tool evenly, without lifting it off the surface for as long as possible.

The composition of decorative plaster is applied directly to the wall with a roller, the texture of the surface is formed simultaneously with the application of the plaster.

When using such tools, it is important to remember that:

- The wider the plaster roller, the easier it is to get the desired effect.

- The convex pattern on the wall surface is achieved using a roller with recesses, and the depressed effect, on the contrary, is achieved due to the relief protruding on the roller.

- It is better to use a roller on a slightly dried coating so that the effect does not “float”.

2. Structural rollers. Unlike the previous type, these tools are used to obtain a repeating complex pattern or ornament on an already applied finishing material.

The structural roller for decorative plaster, as a rule, rubber or wooden, has a clear ornament closed around the working roller. In fact, the use of such a tool creates the effect of volumetric wallpaper on the surface of the plaster.

Such rollers are most often used when applying a liquid composition over an already finished surface, painted or plastered. This is due to the fact that a pronounced relief on the nozzle when rolling the roller over a thick layer of plaster can lead to uneven settling of the material in the cells of the tool, and as a result, the formation of an uneven final coating.

To avoid this, you can:

- Use a roller with a slightly pronounced relief;

- Dry the plastered surface for 20 minutes, and only then, from top to bottom, observing the uniformity of speed, pressure and direction, roll the roller along the wall.

Important: When applying decorative compositions using a structural roller, it is important to ensure that each time the tool passes exactly next to the previous pass. It is not worth retreating and rolling the roller with an overlap, this will negatively affect the result.

Independent production of rollers.

It is not always possible to find a suitable relief roller for plaster in the store, but in this case you can make it yourself. The pattern applied with such a tool will be unique, which will allow you to create an exclusive interior.

To imitate the texture of wood, an ordinary rubber roller is wrapped with a bundle of the same material (for reliability, it is better to put it on glue), turns can be made different thickness and orientation, due to which the “wooden” surface will look very realistic. You can do the same with a plastic roller by wrapping it with a narrow strip of dense fabric.

You can get a textile ornament on the wall by using a smooth roller pasted over with a fabric of the appropriate texture.

Even a simple roller, arbitrarily wrapped with a rope, a tourniquet or polyethylene, can create unique ornaments on the wall and unique textures on the plastered surface.

Wide application can be found for foam rollers, with patterns or grooves of various degrees of curvature cut out on them, so you can achieve both the effect brickwork, and just an interesting vertical ornament. But it is worth remembering that the foam can somewhat deform the final pattern, so using such a roller is very careful.

Patterning technique.

So, the choice in favor of the material for finishing The walls are made - decorative plaster. The technology of applying it with a texture roller is available even to a novice master, but it requires certain skills and accuracy:

- The roller is dipped into decorative composition, poured into a special cuvette, excess plaster is squeezed out.

- It is necessary to apply the composition on the wall from top to bottom (in the future this direction cannot be changed), trying not to tear the roller from the surface to the end of the strip - the quality of the final work depends on this. The pressure and rolling speed of the roller must be uniform.

- Each strip is applied close to the previous one without gaps and overlaps; it is worth applying the plaster immediately to the entire wall so that the borders are not visible.

- Decorative plaster is applied in only one layer, so it is important to ensure that it is of the same thickness.

- If the texture after application seems rough, then you can soften the effect with a brush.

- When using a structural roller, you should wait a bit for the surface to dry, but the longer the plaster dries, the more it loses its plasticity.

- By changing the degree of pressing the roller, you can achieve various effects on the surface of the wall, this technique is useful for emphasizing individual decorative elements.

Important: Rollers for decorative plaster with a large relief visually reduce and narrow the space, this must be taken into account when finishing small rooms with low ceilings.

In addition to interior decoration, decorative coating is used for outdoor work. Particularly popular as a reliable, simple and beautiful finishes serves as a decorative facade plaster under a fur coat For its application with a roller does not require any special skills.

Question price.

The cost of applying textured plaster (for square meter) depends on:

- Type of coating, the most expensive - Venetian and silicone.

- material consumption. On average, the consumption is 1 kg / m2, if the plaster is finely dispersed, then the consumption decreases.

You can buy material at any hardware store, prices vary greatly depending on the type of composition and its manufacturer.

by the most expensive coating(per sq. m) is due to:

- application technology in several layers;

- high requirements for the quality of the base;

- the complexity of working with the composition.

If desired, you can make a decorative composition yourself or order it from the builders. In this case, the price per m2 of the finished coating will be much less.