Sometimes in the course of everyday affairs it is necessary to strip a cable or wire, but not everyone knows how to do it. Many, due to an erroneous idea of \u200b\u200bthis matter, damage the inner rod or completely cut it. There are those who do not know the essence of the difference between wires and cables, but it is!

The wire is considered a special conductor, in some cases it is offered in a "naked" form without the need for stripping. And the cable is offered in the form of many current carriers, connected together without contact, and covered with a special material.

Next, we will figure out how to properly strip the wires, because sometimes they have a multiple shell - the top one and for each element inside. Agree in this case recklessly rely only on the help of a knife.

A set of tools to get the job done

Sometimes it is required to use a special tool for stripping wires, because due to objective reasons only this type is suitable. Most commonly used:

- Side cutters, since almost every owner has them, and are unpretentious in work;

- Mounting, stationery or construction types of a knife - a sharp household option is allowed;

- One of the versions of the electric burner;

- The use of pliers is allowed;

- Specialized versions of cutters designed to work with thick wires or scissors for cutting metal;

- For convenience, a vice or any type of fixture for fixing is suitable.

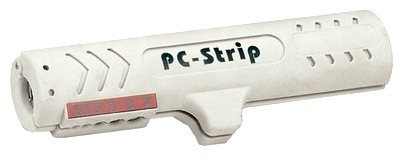

With these devices, you can make an easy option for cleaning almost any wire. Now take a look at the wire stripping photo so that you understand what the various tools look like and the nuances of working with them. But there are special cases that require the use of rare tools. Let's consider some of them:

The stripper can help in a difficult situation, because it was created with one purpose - to help clean wires with high quality. Simplified options for functionality are almost the same as side cutters.

The blades have recesses with different radii for working with veins of a suitable section. And the semi-automatic version has a set of two sponges and blades.

For operation, you will need to put the end of the cable on the working compartment, fix the position and remove the insulation. The upper cover of the insulation is cut with blades, and the rest of it is qualitatively removed with sponges. On the territory of Russia, this version is called KSI (pincers that help remove insulation).

But there are products that help to carry out several operations:

- They cut off the isolation zone;

- Clean up the remains of the insulation;

- Help to qualitatively twist the cores.

Important: When operations with wires or cables are completed, be sure to check their current status. All new connections must be reprotected with insulating tape.

The German manufacturer Knipex produces many high-quality tools for stripping various current carriers. They are often used by professionals because they are verified by various tests based on voltages of 10,000 volts or when exposed to temperatures in the region of +70 and down to -25 Celsius. Because of this, reliability is guaranteed.

This company offers:

- Set of combination pliers;

- Knitting types of pincers;

- Clamping types of pliers;

- Various cutting options;

- An impressive list of multifunctional tweezers;

- Forceps for almost any purpose;

- Cable knives.

What is the process of cleaning the current carrier from insulation?

The explanation is necessary so that you understand how to strip the wire from insulation, and what are the nuances of this process. Usually, a simple side cutter is used for this, since it is this device that is most often at hand from the owners.

But such an undertaking does not always lead to a positive result, since not everyone knows how to use this tool, and damage the inside.

After that, the cable or wire may be dangerous or not able to carry voltage. To prevent this from happening, it is necessary to correctly place the side cutter knives for high-quality entry into the insulation due to the minimum pressure of the fingers.

It is difficult to say which device is better for stripping, since they all differ in positive and negative aspects. And not always there is at least some kind of tool.

In this case, you have to use a knife - press the blade a little on the insulation and make a circular motion. When you manage to reach the core, you can pull off the insulation with pliers or hands, some craftsmen do it with their teeth, which we cannot recommend, because the risk of getting infected with something or swallowing the wire coating is too great.

If there is no knife, then you need to find another cutting element. Usually light stripping of wires is possible with a blade, but this must be done very carefully so as not to cut yourself. You can wear thick gloves, but in them the process of removing insulation can be noticeably complicated.

Let's explain the steps of using the blade:

- An unnecessary razor blade will do;

- After breaking into two halves, use the most convenient and sharp cutting element;

- We recommend securing the wire with a clamp or vise. Sometimes a clip for large table lamps is suitable;

- The insulation is cut along the body of the conductor;

- Careful cross-sectional cuts are required without touching the core;

- It's time to bend the cable and allow the edges in the area of the cuts to conveniently disperse;

- We use a fingernail to remove the insulation - usually this is enough.

Removing insulation from thin or winding types of wires

If the conductor has a thickness of 0.2 mm, we recommend using the mechanical version of the stripping. Various approaches can be used for this:

Using sandpaper, you can create excellent conditions for stripping. To do this, it is bent with the abrasive side inward to form a vicious circle. A wire is placed in it - by light pressing, the necessary part of the insulation coating is gradually removed.

With a knife, you can carry out a similar procedure. It is necessary to lay the wire on a solid base. Bring the blade to the insulation, and gradually twist the wire until the coating is completely removed.

If the thickness of the conductor is less than 0.2mm, the mechanical version will not work and will most likely severely damage the strand. But you can use the thermochemical option to get rid of insulation.

To work with vinyl chloride insulation, a soldering iron is used:

- We put the wire based on vinyl chloride insulation on a comfortable coating;

- We heat up the soldering iron and carefully drive along the insulation coating;

- From heating, chlorine will begin to separate from the coating and it will disappear;

- To complete the work, you must use an aspirin tablet. It is placed on the wire and heated with a soldering iron - gradually distribute it throughout the wire.

The latter method is complex, but do-it-yourself wire stripping is also possible based on it. It is necessary to take into account the minimum size of the section and the presence of many cores twisted into one whole inside the cable. But taking into account the careful implementation of any of the proposed options for removing isolation, the operation is available to any owner.

Photo of the wire stripping process

Among the household tools, the owner must also have devices for working with electricity. If there are problems with electrical wiring, it often needs to be replaced, but there is a possibility of a simple repair, during which you cannot do without a device such as wire stripping pliers. Even knowing the basics of working with electrical networks, it is imperative to use additional equipment in the form of useful tools.

Experienced electricians insist on the use of a stripper (as the pliers are scientifically called) to remove insulation from conductors. It happens that self-repair of the electrical network leads to negative consequences. First of all, this is due to the use of a conventional mounting blade. Using improvised material, it is impossible to guarantee the accuracy of removing the insulating layer. Failure to comply with the requirements violates safety rules, the overall integrity of the structure and the length of the insulation of the conductor may not meet the standards. Subsequently, the requirements that apply to electrical cables do not meet the standards of the PUE and GOSTs.

Important! To avoid numerous mistakes when installing power supply systems at home, professional tools should be used.

A stripper is used to remove insulation from wires - this is an item used in electricity of any profile. Its main characteristic is a long service life and reliability in operation.

Professional wire stripping pliers

It is customary to divide models into several classes, namely:

- simple tools, used in conditions where there are no complex steps, that is, often found in the installation of household electrical appliances. The model is a bit similar to the side cutters and is used to strip individual cable cores from the insulating coating;

- stripper machine - such a tool was created according to all the rules. The working mechanism consists of two pairs of soft pads with sharp blades. The device is used as follows: the end of the conductor is placed in the pliers, when clamping, the blade creates pressure on the insulation layer, and the sponges gently and sharply remove the cut layer;

- stripper in the form of a clerical knife. Consists of two blades and is designed to cut the insulation of twisted wiring;

- device for working with coaxial cable. External qualities resemble the previous device, it is distinguished by a replaceable clamp, which is installed to work with wires of a certain section. Of the shortcomings, only the complicated adjustment of the device;

- pliers for power cables. The tool is made in the form of a clamp with a floating blade. The unique blade design can cut the insulation layer lengthwise and across;

- clip to remove the varnish layer. The device is reliable, but very simple at first glance. Such an item meets all the requirements and standards of production.

Stripping device: important features

Today's example of our article was the WS-04B device from the KBT trademark. Its most advantageous quality is versatility. Such pliers are mainly used in the professional field. No exception - the high performance of the device and ease of use, so it is acceptable to use the device, and for the installation of home electrical networks. Nippers for removing insulation from wires of the proposed model have the ability to work with several sections of conductors ranging from 0.2 to 6.0 square meters. mm. Thanks to the convenient design of the pliers, it is possible to accurately press the ends of the wire strands, as well as to cut the wire.

Mechanism of stripping pliers

One of the excellent characteristics is the equipped automatic mechanism in the device, which independently determines the size of the wire section. The micro-adjustment screw is used to work with cables with a minimum cross section. The use of a wire stripper makes the process easier and simpler. Thanks to a professional idea, the stripper removes the insulating layer without damaging the copper or aluminum conductor.

Important! Use only a quality stripper, otherwise, you will face damage to the cable cores..

Stripping pliers set

The principle of operation of the tool or how to remove insulation from a copper wire?

With the help of pliers, it will be possible to remove the insulation very simply even from the smallest sections of the cores, depending on the capabilities of the device.

- When the wire penetrates the device, the blades cut perfectly into the insulating layer, there is a double-sided grip by the pillows. Please note that the conductor is held by those pillows that have corner notches.

- The other side holds the insulation, which is then thrown away.

- Then there is a sharp jerk and the divergence of the pillows in different directions, and this entails a rupture of the insulation material.

- At the last stage, the broken insulation is removed.

A metal plate, additionally equipped with plastic covers, is responsible for the relatively sharp jerk of the tool. As a result of pressure on the handles of the device, the plate rises and creates a divergence of the mechanism. In order for the metal pads to clamp the conductor, it is enough to slightly press on the handles of the tool.

Important! The pull force of the stripper can be adjusted with a micro screw.

As a result of the work, a well-prepared bare conductor with no damage is obtained, and all this is due to a universal device.

When wiring any complexity, there is almost always a need to strip the wires. Some try to do this with their teeth, but there is no need to even talk about the absurdity of this method - you must use at least the minimum suitable devices for this purpose - a knife, pliers, wire cutters or professional tools.

Electrician's knife for cutting cables

With the development of electrical engineering, many methods have appeared for removing the insulating coating from conductors. The most obvious is cutting or cutting with a knife of the insulating sheath and then removing it.

Many electricians still use this method if a specialized tool is not at hand. An electrician's knife can be either homemade or industrially produced for electrical installation.

It takes practice and care when stripping wires, especially stranded wires, with these cutting tools. Since this is a rather troublesome process, professional electricians rarely use them for these purposes, but an electrical knife is almost indispensable when cutting cables, that is, when removing the top layer of insulation.

removal of the top layer of insulation

removal of the top layer of insulation Especially popular is a knife with a heel on the tip, which slides along the inner insulated cores of the cable, cutting the outer insulating layer.

This heel is carefully inserted into the end of the cable and pushed away from you or towards you, as it is more convenient for you, cutting the upper protective coating with a sharp cutting edge.

To make it convenient to insert the heel, the cable is compressed with pliers.

For safety reasons, in order not to get hurt, it is recommended to always hold the cable with pliers during these manipulations.

For safety reasons, in order not to get hurt, it is recommended to always hold the cable with pliers during these manipulations.

Wire stripping methods

The insulating cover is removed from the cable cores by various methods and tools that are most suitable for a certain type of insulating cover.

Since conductors with PVC insulation are most often used for the installation of household electrical wiring, we will only talk about tools suitable for this work, but first it is worth mentioning some artisanal methods for removing the insulating protective cover. For lack of better tools, knives of various designs are most often used.

Often, the PVC insulating layer is melted with a soldering iron, after which the insulation is removed with pliers.

A significant disadvantage is the poisonous evaporation and corrosion of the soldering iron tip. A similar heat treatment is also carried out using a lighter or a heated nichrome thread.

Another way is to compress the wire with wire cutters and tighten the insulation, with a verified compression force, which is difficult to control - by pressing a little harder, you can easily bite through the metal core.

These methods are suitable for one-time stripping of several wires, but in professional activities you need an appropriate tool for stripping.

Principles of stripping current-carrying cores

There are two principles for removing the protective cover from cable cores used in professional tools - this is cutting and breaking the insulation.

When cutting, the cutting edge, without damaging the current-carrying core, cuts through the protective layer in a circle, after which the resulting cut tube is removed from the conductor with some effort. This principle is used in a simple stripping knife.

The wire is inserted into a semicircle of a suitable radius, located on the pressure plate, after which the tool is rotated several times around the core and the insulating layer pressed against the blade is cut in a circle. A similar method is used in another cutting tool - here the clamping force on the blade and the diameter of the wire to be peeled are manually adjusted by pressure.

Other modifications:

The disadvantage of these devices is the operation time and the possibility of damage to the metal core.

Rupture and stripping

This principle can be compared to the method of stripping wires with teeth, when a piece of clamped insulation is torn off from the rest of the coating when a force is applied along the conductor.

Such professional tools are called strippers, they allow you to strip the insulation very quickly, with one touch of the handle, which makes them very beneficial for large volumes of wiring.

The stripper (striper, a derivative of the verb to strip - bare) is designed in such a way that three functions are simultaneously performed in it:

- Fixing the wire to be cleaned;

- Compression (biting) of the insulating layer;

- Pulling and pulling force.

The fixing jaws are notched so that they can hold the cable core firmly. The tearing jaws are equipped with grippers that bite the plastic layer, partially damaging it when pressed, due to which the insulation is torn precisely in this place.

This stripper is equipped with a wire stopper, so all wires will be stripped to the same distance, which can be adjusted.

This stripper is equipped with a wire stopper, so all wires will be stripped to the same distance, which can be adjusted.

The force that pushes through the insulation is adjusted using the adjustment screw.

A similar principle of wire cleaning was used in the Soviet stripper, only it did not have a limiter, and it was necessary to insert the wire into the corresponding semicircles.

Stripper using scoring blades

The principle of cutting insulation, followed by its removal, is used in the Knipex stripper.

Here, the same functions are used as in the tool described above, only instead of squeezing the PVC layer, it is notched, but structurally this stripper is made of reinforced carbon fiber.

The insulation removal algorithm is as follows - inserting the wire, fixing it, cutting and removing the cover.

This tool also has an adjustment for the length of stripped insulation and the depth of cut of the blades.

This tool has the ability to cut cables.

In addition, with this stripper, you can cut the wires.

Regardless of the method, tool, or stripper used, when stripping, care must be taken to properly set the stripping tool so as not to damage the strand, which can then break off.

The work of an electrician is often associated with the use of different devices. To perform a common operation in the form of stripping wire and other electrical devices, stripping tools are needed. The most convenient tools are special pullers and strippers.

But, if you need to strip two or three cables, then you can use a simple kitchen knife. If you plan to work on laying electrical wiring in a house or apartment, then an ordinary knife will not be enough for such a task. The kitchen knife has an awkward blade, and the handle may not be made of dielectric.

Types and arrangement of electrician's knives

A knife adapted for work on connecting electrical appliances has a special blade shape. Often on the wires it is necessary to make circular cuts in the insulation, which is more convenient to make with a curved blade. Many will say that you can remove the insulation with a simple knife, but if the knife does not meet certain conditions, then it is easy to damage the conductive core, especially the thin one.

For the convenience of making circular cuts in the insulation, the blade may have recesses for wires of various diameters. Having placed the wire in this recess, the braid is cut in a circular motion, without fear of damaging the current-carrying core.

Knife with heel

This knife belongs to electrical types, and has another name for a "plow" knife. It is convenient for them to remove the insulating sheath, as it has a curved short blade with a special “heel”. It is designed to limit the depth of the sheath cut when it is necessary to remove the outer layer without touching the inner layers of the insulation.

We must not forget to check the absence of voltage in the wiring before stripping the insulation.

The platform at the end of the blade reduces the friction of the longitudinal sliding of the knife during the removal of the outer sheath, and does not allow the blade to touch the internal wires. It is convenient to strip hard cables with a knife, and it is worse to work with soft sheaths, as they make it difficult to slide the “heel”. In general, stripping tools like a heeled knife are useful for electricians to use.

Hook knife

This electrician's knife is a professional tool. This knife has a straight and short blade with a hook. There is no sharp edge on the blade, except for a sharpened hook. The same models are available with an extra sharp edge on the other side of the blade. This model is well suited for stripping insulation on many.

It is especially convenient to cut the insulation along the wire with such a blade. There are also similar models equipped with devices for making circular pre-cuts.

Knife with a beak

Such stripping tools have a specific blade shape, which is why many electricians do not use it. A knife with a "beak" may be convenient only for experienced electricians, its blade is a bit like the previous design, with the difference that there is no "heel" at the end, and the bend is smoother.

Such a beak-like curved inner point makes it more convenient to cut the wire sheath in a circular manner. This knife can also be used by electricians for longitudinal cuts, but doing this work inaccurately can damage the core, since there is no limiter. For novice electricians, such a knife is inconvenient due to manual adjustment of the cutting depth.

Requirements for electrical knives

- The handle of the knife must be made of dielectric material of sufficient strength: carbon fiber or special plastic, to prevent electric shock.

- The blade must be made of durable steel to maintain its sharpness for a long time.

- The shape of the handle should allow the electrician to feel the beginning of the blade by touch.

- The sharp edge should be straight to make it easier to cut double insulated cables.

- The knife should be chosen small, which makes it possible to work in a small space, for example, in a cabinet or shield. The blade should also not be too large, so as not to accidentally damage the insulation of adjacent wires in the wiring harness, and also for the convenience of stripping thin conductors.

- An electrician does not need a knife with a pointed end of the blade to work. When working in dark and cramped places, you can accidentally touch the sharp end with your hands and get injured. When working with a wiring harness, the sharp end of the blade easily damages adjacent conductors.

- When removing the insulation, the blade must be held at an acute angle to the wire so as not to damage the current-carrying core. The shell should be cut carefully away from you, in pieces, according to the principle of sharpening a pencil.

- A factory-made quality knife should have a designation of permissible voltage on the handle.

- If a homemade knife is used, then its handle must be wrapped with insulating tape or other dielectric material.

Pullers

There are special tools for stripping wires from insulation. They are a versatile tool for stripping conductors, and can be equipped with several cutting elements of various lengths and configurations. But the main element is a special clamp, with which a circular cut of the insulation is made.

These stripping tools are the most convenient. They allow you to manually select the wire diameter without fear of damaging the core. It is not difficult to work with such a device, it is enough to fix the wire in the clamp, and make one turn of the rotational movement around the wire with the puller.

Strippers

Strippers have become the most common type of equipment for stripping the insulating sheath of cables among professionals. With their help, it is much easier to strip the insulation, especially from wires that have many cores. The cutting depth is adjustable, which makes it possible to use the stripper for any cable diameter.

There are several types of strippers that differ in their design, but their principle of operation is the same: cutting the insulating sheath and removing it from the cable.

Manual strippers

These stripping tools work simply. The design is similar to pliers, with the difference that the jaws have nests with cutting edges for different sections of the cores. This type of tool is suitable for stripping wire insulation no more than 6 mm 2.

Some models are capable of crimping tips. To remove the insulation, you need to place the wire in the socket, press the handles and perform a circular rotation.

Semi-automatic strippers

This tool is even easier to use. Its device has been improved in comparison with the previous model. No need to rotate the stripper around the cable, just fix the wire in the appropriate socket and press the handles. Many models of semi-automatic strippers are capable of crimping ferrules and cutting cables.

Automatic stripper

Such stripping tools are professional types of strippers. It differs from the previous model in that it independently determines the thickness of the conductor. Therefore, all the work is to install the wire in the right socket and apply force to the handles.

Automatic wire strippers are expensive products, they can strip the insulation from several conductors at once, as well as strip the wire in its middle. There are also automatic strippers for stripping flat wires, and for many other purposes when doing electrical work.

How to choose stripping tools

For home work on connecting electrical wiring, it is advisable to purchase a manual stripper for stripping insulation, which is capable of stripping wires up to 6 mm 2. Manual stripping tools are inexpensive and have enough functionality for home craftsmen.

For professional electricians who are constantly laying lines of wires and connecting them to various devices, it is better to purchase an automatic stripper, or at least a semi-automatic model. Their cost is correspondingly higher, but the electrical installation of the wiring is greatly simplified.

How to use the stripper

Let's consider this question on a Chinese semi-automatic stripper, which has been working properly for several years.

The cutting part is two plates with cutouts for different wire sections.

When placing the conductor in the grip, you should leave part of the wire for stripping behind the knives.

We squeeze the stripper handles, holding the conductor with our hands. In this case, the knives are compressed, cutting the sheath, and the sponges pull the conductor back. As a result, the wire sheath is removed.

A feature of working with a stripper is the correct choice of the size of the cut. If you choose its diameter incorrectly, then the conductive core will be damaged or even break off. You should not capture too much length of the shell, it is better to remove it in several passes. With sufficient skill with the stripper, the insulating sheath is removed in less than a second, and the job goes faster. Therefore, the purchase of such a tool saves working time, finances and the strength of the employee.

Crimping tips with a stripper

If there is no special tool used for crimping wires (crimper), then this work can be done with a stripper. This work is quite simple. First you need to strip the wire from the insulating sheath to the required length. Next, install the ferrule on the wire and place it in the appropriate connector of the stripper. Then you need to squeeze the handles, getting a crimped wire in the tip. Then you should cut off the excess end of the core.

Advantages of strippers

- In addition to stripping, they can be used instead of press tongs or wire cutters to crimp the wire.

- These stripping tools can be used to strip very thin wires.

- It is allowed to use strippers to remove the sheath from conductors with any type of insulation.

- During operation, they do not damage the conductive core, even made of soft metal.

- Simple and clear usage.

- Low cost.

Stripping the insulation with a soldering iron

If there was no special tool or knife at hand, then you can strip the cable or wire with a simple one. To do this, it is heated to operating temperature, then a conductor is leaned against the sting and rotated around its axis, melting the insulation.

Now the insulating sheath can be easily removed, and the core will not be damaged. The disadvantage of this method is the release of harmful and unpleasant smoke by the melting insulation, as well as the impossibility of using a soldering iron to strip the rubber wire, since the rubber will burn.

Any work with electrical wires creates a need to remove the braid from the conductors. In certain cases, regardless of whether partial or complete removal of insulation is required, this procedure is of great functional importance, whether it is home wiring or industrial wiring.

In this case, a stripper will become an indispensable tool, the purpose of which is to perform the function of removing the insulation of wires as separate elements or the entire wiring as a whole. What this tool is can be seen in the photo of the stripper.

In the past, conventional dismantling knives did a good job of this process, but this process caused quite a large-scale danger and had no replacement. In addition to the outdated method, the requirement for certain skills and abilities was added, which not every master could possess.

In this direction, the stripper has no equal, since absolutely anyone can handle this tool, even a home craftsman who has never held it to the point of need. In addition, unlike the knives used in the old days, the stripper carefully removes the braid from the wires without touching the core itself.

It should be noted that before starting work with the removal of insulation, an important factor will be the de-energization of the wiring, since otherwise you can get an electric shock.

If there is no such possibility as de-energizing the wiring, then you should definitely make sure that the stripper handles are made in the dielectric type, in other words, they do not conduct current.

Types and characteristics of strippers

Considering all types of strippers, there are three main types of them, however, on the market of the tools presented, you can easily find other types of this model, which will cost indecently expensive and have the same functionality as conventional ones. Instructions on how to use the stripper are indicated in the description of each of its types.

Manual wire stripper

This type of tool is commonly called mechanical, which you should definitely keep in mind when going for their purchase. It bears such a name because of its capabilities, that is, in order to use this type of stripper, it is necessary to apply some mechanical actions.

A manual stripper can be easily confused with conventional pliers, since its design is very similar to the last tools - two handles, a hinge and lips, however, the stripper has recesses on the lips, with the help of which the insulation is removed from the wires.

When choosing this tool, you should pay attention to the number of nests located on the lips, as well as to the digital designations of the section diameter - all this greatly affects the final price of the product.

The undoubted advantage of this type of stripper is its multitasking, due to the fact that it can bite off wires of small diameter in cross section. In addition, the manual stripper has the ability to compress a large number of wire lugs into one single core.

Moreover, it can be used as pliers, but it is not intended for this role at all and should not be forgotten.

For each model, there is a single order of steps designed to properly work to remove the braid from the wires, namely:

- It is important to accurately determine the diameter of the wire and select the socket on the lips of the stripper according to the required value.

- Place the wire in a suitable recess

- Bite the wire by pressing the handles of the tool

- Remove the braid from the wire by moving in a circle

Attention! There is a possibility of damage to the wire itself under the braid if the diameter of the section of the socket itself was incorrectly selected, otherwise (when choosing a larger socket) the insulation will not be removed - it is necessary to accurately select the socket for the diameter of the wire!

The standard price of a manual stripper is 500-1000 rubles.

Semi automatic stripper

A more expensive, but also the most convenient option would be a semi-automatic stripper. The main advantage, unlike a manual stripper, is the ability to remove insulation from several cores at once, as well as the absence of the need for mechanical actions due to the specific design of this type of stripper.

Outwardly, it is practically no different from a hand tool, but there is a different order of work:

- Selection of the required recess on the lips in accordance with the diameter of the wire section

- Placement of the core in the desired socket

- Applying pressure to the handle and stripping the insulation

There is no need to take actions other than those indicated, since the rest of the process occurs automatically. It is precisely because of this property that many masters prefer this type of semi-automatic stripper compared to manual. However, there is an even more significant version of the stripper, which will be discussed later.

Note that the design of the semi-automatic stripper has a limiter that will not allow you to remove the insulation from the wire beyond the selected value.

The usual price for a semi-automatic stripper ranges from 1000 to 2500 rubles.

Automatic stripper

Basically, this type of stripper is no different from the previous one, except for its main advantage - the lack of a requirement to select a suitable nest. Its entire essence is contained in a single socket, suitable for absolutely any diameter of the wire section.

Unlike the previous two types of tool presented, the automatic stripper gently removes the insulation from the wire without any damage to the wire itself. Of all the actions that need to be performed to remove the braid, you only need to install the stripper on the wire and press the handle.

Fortunately, any beginner can handle this type of tool, because the insulation is removed automatically.

The undoubted advantage of this automatic mode device is its operability even with the smallest wire cross-section, since there is a detailed adjustment in place of the jaws.

The only remark about this device is the setting of its socket for wires of various sections, so this element is not able to strip insulation from all types of wires, you should definitely take this parameter into account when choosing an automatic stripper.

In addition to all of the above, this type of stripper is also capable of crimping wires, creating a single wire from several, cutting wires like wire cutters and performing the functions of some other tools.

The price of an automatic stripper varies from 2000 to 5000 rubles.

Which stripper is better to choose

You should not choose a tool only for its intended purpose, it may be able to perform the functions of another, you should definitely choose a stripper according to the required conditions.

Similarly, with rare use, it will not be superfluous to think about the price range of the stripper being purchased, since in this case it is not necessary to buy an expensive tool.

However, if a stripper is required for daily work in the field of industrial electrical, an automatic stripper or a multifunctional one will be the best choice, while for home work a manual or semi-automatic type can be dispensed with.

Also, the choice is influenced by the material with which one tool can handle easily, while the other may have difficulties.

Photo strippers